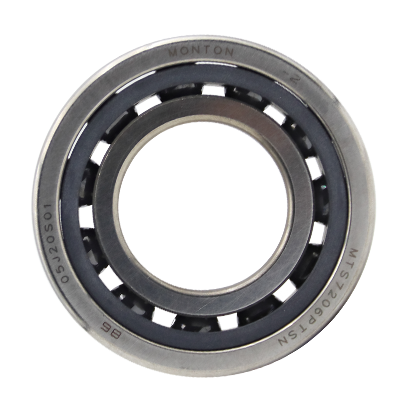

Ball Screw Support Bearing from Monton Bearing

Monton Angular contact thrust ball bearings for precision ball screws have been designed specifically for each application. Lineup includes both a highly rigid series and high capacity series.

All ball screw support bearings are nonseparable angular contact bearings and have cutaway shoulders on both the inner and outer rings.

They can support very high thrust loads in one direction or combinations of radial and thrust loads, but not radial loading alone. These bearings are designed to provide machine tool drive systems with extreme axial rigidity, low drag torque and minimal axial runout. They are intended for specific applications in machine tools, e.g., ball screw supports, cross slides, X Y table positioners and transfer tables. They should not be used in place of standard angular contact spindle bearings.

BS Series bearings have a molded nylon, glass fiber reinforced polyamide cage with spherical ball pockets.

Inch Series, L bearings, have a landpiloted cage of reinforced phenolic, precision machined, with evenly spaced ball pockets.

All metric (BS, 7602, 7603 Series) ball screw support bearings come with the molded nylon cage, standard. Series L bearings are equipped with the phenolic cage, standard.

Bearing pairs and sets are matchmarked on their outside diameter surfaces to indicate correct positioning of each bearing. Barden packaging also contains detailed instructions for proper installation.

Recommendations for shaft and housing shoulder diameters are based on maximum support of duplexmounted bearings as found in the product tables. In circumstances with other mounting arrangements, consult Barden Product Engineering.

Most ball screw support bearing applications are subject to duty cycle loading with constantly changing feeds, speeds and operating loads. These factors, in combination with the heavy preloads built into the bearings, make life calculations difficult. Consult Barden Product Engineering for information which can be used in specific cases.

Ball screw support bearings (rings and balls) are made from 52100 steel. Bearings are also available with X life ultra rings and ceramic (silicon nitride) balls for even greater speeds and longer life.

Ball screw support bearings are available as singles, standard duplex pairs or quadruplex sets. In addition, we will supply custom combination sets to meet specialized application needs.

Ballscrew bearings could be designed into sets of two, three, four or various other combinations in order to meet a ballscrews loading requirements. Ballscrew bearings can be arranged into either a face to face or a backto back duplex bearing. These types of ball bearings can handle the loading force from both the axial and radial directions, and by increasing the number of ball bearing sets will improve their loading capacity.

For a back to back configuration, there is a large distance between the acting load center of the bearings resulting in a higher moment load capacity. Therefore, this kind of bearing arrangement is commonly used in machine center spindles. Although the moment load capacity for a face to face configuration is smaller, it has an advantage of having a larger misalignment angle.

DRZ ballscrew bearings have a contact angle of 60°. This type of bearing can handle

larger axial loads when compared to the normal type. It is specially designed to be used

in ballscrew assembly. Since the axial load capacity is high, this also provides a high axial

stiffness . This could prevent the ballscrew from shifting when loaded . The functionality of ballscrew bearings is to help the ballscrew reach it's best accuracy .

Seal is integrated into a ball screw support bearing with great axial rigidity.

Maintenance free because high performance grease is pre-filled

(Prevents entry of foreign substance from outside.)

Preset preload for easy installation onto the machine.

Contact and non-contact seals are available.

Universal flush ground bearings are also available.

With plastic cage, more balls are incorporated than conventional angular contact ball bearing to increase rigidity.

Energy saving thanks to excellent low starting torque and rotational torque.

Preset preload for easy assembly onto the machine.

Contact type seals with excellent sealing performance and non-contact type seals with reduced torque loss and temperature rise are available.

Maintenance free with grease filled

Application:

Used in high precision,

high-speed precision machine tools.

Precision measuring instruments and precision feed actuators such as robots.

Previous: Monton spindle bearings

English

English Russian

Russian Chinese

Chinese