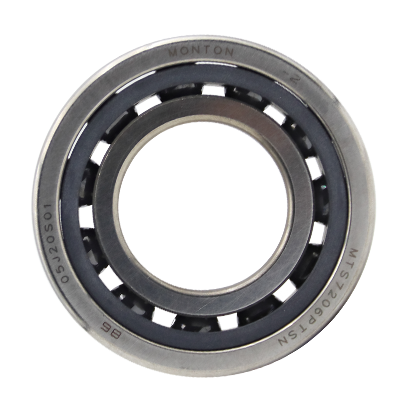

Hybrid Bearings

Many machine repairers are upgrading to hybrid - (steel ringed bearings using silicon nitride ceramic balls) in order to improve reliability, particularly in situations where warranties are extending from 1 to 2 and sometimes up to 3 years.

Features of Hybrid Bearings – Lighter Weight

Due to mass being approximately 40% of steel, hybrid bearings can run up to 25% faster than conventional

all steel bearings. This also means that the generated temperature is also lower.

Smoother Surface

The surface finish of the ceramic ball is much smoother than the steel ball, this improves the accuracy of rotation and the part being manufactured.

Harder and Stiffer

The ceramic ball is much harder than a conventional steel ball (HV 1700@ <800°C compared to HV 700@20°C). This means that the ceramic ball is less likely to be damaged by small

amounts of hard contamination. Higher stiffness means that the hybrid bearing will distort less under high load compared to the steel ball type.

Corrosion and Electrical Resistance

These bearings can be run in more arduous environments. The electrical resistance prevents pitting of the ball surface due to electrical discharge in built-in motor spindles.

Designation System:

7014CSN24TRSULP3 (Standard Precision Product)

70BNR10HTSULP3 (High-speed ‘Robust’ Product)

Summary of Benefits

› Higher Speed

› Cooler Temperature

› Higher Reliability

› Longer Life

› Higher Accuracy

Previous: Innovative Components and Systems for the Next Generation of Machine Tools

Next: Innovative New Gearbox Roller Bearing for the Wind Energy Industry

English

English Russian

Russian Chinese

Chinese