Tungsten Carbide Radial Bearing

Tungsten Carbide Radial Bearing

Tungsten Carbide Radial Bearing

Tungsten Carbide Radial Bearing

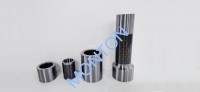

Tungsten Carbide Radial Bearing is used as antifriction bearing for downhole motor. We have three different types from size 54 to size 286 for your choice (a total of 14 size). Besides, we can design and manufacture related TC bearings according to the specification of custome

We can

Tungsten Carbide Radial Bearing

Tungsten Carbide Radial Bearing is used as antifriction bearing for downhole motor. We have three different types from size 54 to size 286 for your choice (a total of 14 size). Besides, we can design and manufacture related TC bearings according to the specification of customers:

We can supply three kinds TC radial bearings:

1.TC Tile Bearing

TC Tile Bearing:Hard alloy covering rate reach more than 55%

2. TC Grain Bearing

TC Grain Bearing: Hard holly ball with diameter of 0.7-1.2mm makes it more suitable for small and complicated TC.

3.TC Disc Bearing

TC Disc Bearing: Hard alloy covering rate reached to more than 80%. It has a longer life and more antifriction.

Performance:

1) Highly resistant to abrasion, erosion, corrosion, and mechanical failure

2) Extremely resistant to chipping, cracking, and flaking which are inherent problems in cladding or welded overlay processes

3) High heat conductivity eliminates thermal cracking

4) Proprietary design eliminates catastrophic downhole radial bearing failure

5) Carbide tile and matrix design ensures extended life compared to cladding or welded overlay designs

6) Inner and outer components can be reconditioned.

7) The hardness of body surface can reach 30-37 HRC.

High strength,long life inserted cemented carbide radial bearing is a proprietary product of our company (the largest and earliest company to manufacture radial bearings). Cemented carbide and special welding materials and cemented carbide additives regularly placed on the inner and outer surfaces of the radial bearing are fused with the based of the radial bearing through specific sinter processing. Its friction pair is featured by corrosion resistance, shock resistance, heavy load bearing and long life, and its appearance quality and technical indicators are superior than the similar products of other countries.

supply three kinds TC radial bearings:

1.TC Tile Bearing

TC Tile Bearing:Hard alloy covering rate reach more than 55%

2. TC Grain Bearing

TC Grain Bearing: Hard hoy ball with diameter of 0.7-1.2mm makes it more suitable for small and complicated TC.

3.TC Disc Bearing

TC Disc Bearing: Hard alloy covering rate reached to more than 80%. It has a longer life and more antifriction.

Performance:

1) Highly resistant to abrasion, erosion, corrosion, and mechanical failure

2) Extremely resistant to chipping, cracking, and flaking which are inherent problems in cladding or welded overlay processes

3) High heat conductivity eliminates thermal cracking

4) Proprietary design eliminates catastrophic downhole radial bearing failure

5) Carbide tile and matrix design ensures extended life compared to cladding or welded overlay designs

6) Inner and outer components can be reconditioned.

7) The hardness of body surface can reach 30-37 HRC.

High strength,long life inserted cemented carbide radial bearing is a proprietary product of our company (the largest and earliest company to manufacture radial bearings). Cemented carbide and special welding materials and cemented carbide additives regularly placed on the inner and outer surfaces of the radial bearing are fused with the based of the radial bearing through specific sinter processing. Its friction pair is featured by corrosion resistance, shock resistance, heavy load bearing and long life, and its appearance quality and technical indicators are superior than the similar products of other countries.

English

English Russian

Russian Chinese

Chinese