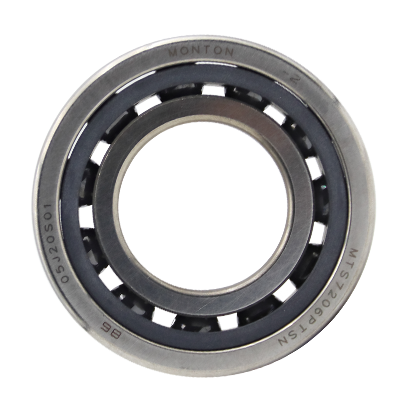

Micro turbojet Ceramic bearing revolution

In the precision world of micro turbojet engines, hybrid ceramic ball bearings are becoming the key to breaking through performance limits. This type of bearing uses a combination of silicon nitride ceramic balls and steel rings, exhibiting excellent performance far beyond traditional metal bearings at extreme speeds of tens of thousands of revolutions per minute. The density of ceramic balls is only 40% of that of steel balls, significantly reducing the contact stress caused by centrifugal force and effectively suppressing the expansion of micro peeling defects. This characteristic is particularly important in the compact space of micro engines, providing more stable support for the rotor system.

The high-temperature stability of ceramic materials endows bearings with unique advantages in the high-temperature environment of micro turbojet engines. Silicon nitride ceramics can maintain strength and hardness at high temperatures, avoiding common softening problems in metal bearings. Meanwhile, its excellent corrosion resistance extends the service life of bearings under harsh working conditions. With the advancement of materials science and manufacturing technology, hybrid ceramic ball bearings are driving the development of micro turbojet engines towards higher speeds, longer lifespans, and higher reliability, providing a stronger "heart" for micro aircraft such as drones.

In the design of micro turbojet engines, hybrid ceramic ball bearings (a combination of silicon nitride ceramic balls and steel rings) significantly improve the maximum speed of the rotor system. For example, when a certain type of micro turbojet engine adopts such bearings, the speed increases from tens of thousands of revolutions per minute supported by traditional metal bearings to a higher range, while the contact stress caused by centrifugal force is significantly reduced, effectively suppressing the expansion of micro peeling defects. This improvement directly enhances the stability of the engine during high-altitude or high-speed flight, providing a more reliable power core for small aircraft such as drones.

China's breakthrough in ceramic bearing technology provides support for practical applications. For example, through the third-generation anti fatigue technology, the bearing life has been increased from thousands of hours in the early stages to tens of thousands of hours. In micro turbojet engines, such bearings are usually installed at the support points of the compressor or turbine rotor, combined with precision lubrication seal design, effectively preventing high-temperature gas leakage and oil pollution, and improving overall system reliability. These innovations not only optimize engine performance, but also drive the development of micro aircraft towards higher efficiency.

Previous: Monton bearing official homepage

Next: How to correctly install and remove the bearings of the extruder gearbox?

English

English Russian

Russian Chinese

Chinese