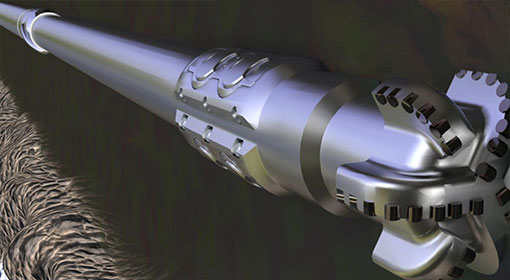

Downhole mud motor

Downhole mud motor

A mud motor (or drilling motor) is a progressive cavity positive displacement pump (PCPD) placed in the drill string to provide additional power to the bit while drilling. The PCPD pump uses drilling fluid (commonly referred to as drilling mud, or just mud) to create eccentric motion in the power section of the motor which is transferred as concentric power to the drill bit. The mud motor uses different rotor and stator configurations to provide optimum performance for the desired drilling operation, typically increasing the number of lobes and length of power assembly for greater horsepower. In certain applications, compressed air, or other gas, can be used for mud motor input power. Normal rotation of the bit while using a mud motor can be from 60 rpm to over 100 rpm.

Down-hole motors can be used successfully in conventional or straight-hole work, and are no longer limited to directional drilling. Recent development work and field tests involving hydraulics, bit design, and stabilization have defined the conditions under which down-hole motor costs and performance can be optimized in straight-hole drilling.

Introduction

The possibility of using a down-hole motor to power a drill bit was first recognized in 1873 when a U. S. patent was issued covering the down-hole rotary patent was issued covering the down-hole rotary hydraulic motor. Conventional rotary drilling was later patented in 1884, and since that time an increasing patented in 1884, and since that time an increasing effort has been aimed at finding improved drilling tools or systems to reduce drilling costs.

One approach to improving drilling practices has been to design and test a variety of down-hole motors. These have included mud-driven turbines. positive displacement mud motors, and electrically positive displacement mud motors, and electrically powered motors. Of these types, the most appealing powered motors. Of these types, the most appealing have been the turbines and the positive displacement mud motors, since mud is already used to remove cuttings from the wellbore in most drilling operations, its presence makes it a likely candidate for providing presence makes it a likely candidate for providing power to a drilling motor. power to a drilling motor. Mud-driven turbines have been under continuous development in Russia since the late 1920's or early 1930's, and their use of the turbine as a practical drilling technique was announced in the early 1950's. In 1955, development work on a positive displacement down-hole motor began in the U. S. The first effort was directed toward straight-hole drilling; but the tool was not considered economical because of bearing problems and because of the lack of bits capable of operating at high rotational speeds.

However, the motor did prove to be an economic and technical success as a directional tool. Since the early 1960's down-hole motors have performed thousands of successful jobs. They have been effective in drilling rat and mouse holes, in controlled directional drilling, side tracking, and hole straighteningall in a variety of formations both onshore and offshore.

As wells are drilled deeper and costs continue to rise, it becomes even more desirable to locate the power to rotate the bit near the bit itself, and not at power to rotate the bit near the bit itself, and not at the surface. Drillpipe torque and tensile strength requirements, the quality and cost of drillpipe, and damage to the hole and to the protection casing can be minimized by having the rotating power at the bit.

Considering these advantages, recent developments in down-hole motors have again been aimed at straight-hole drilling. Key improvements in this direction have been in the areas of horsepower output and bearing design. These improvements have made it possible to increase both the penetration rate and the duration of the run to more nearly match the performance of the diamond bit. Development work is performance of the diamond bit. Development work is still proceeding, but a considerable amount of data can now be presented to illustrate the present state of the art.

The results of an extension field test are shown in Table 1, and provide the basis for an accurate comparison of conventional drilling vs drilling with downhole motors.

Previous: Oil drilling

Next: Mechanical Transmissions

English

English Russian

Russian Chinese

Chinese