B719XX extremely light Series Angular Contact Ball Bearings

|

|

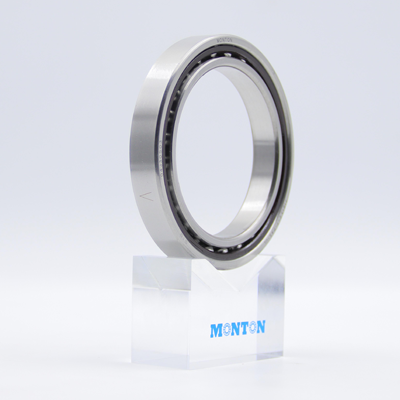

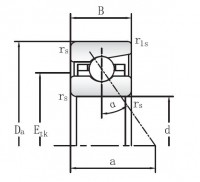

MONTON B719XX extremely light Series Angular Contact Ball Bearings diameter from 10-670

mm . B719XX extremely light Series Angular Contact Ball Bearings are mainly used in applicationwhere available space is limited. They are high-speed bearings with a compact cross-section

design. MONTON offers products with light series contact angles of 15°, 20° and 25°.

Ultra-light series angular contact ball bearings can use small or large balls, steel balls or

ceramic balls, open and sealed bearings, DLR designed bearings, and ultra-light series angular

contact ball bearings with smaller contact fit and small steel balls. Therefore, it can adapt to

very high speeds, and the same inner diameter bearing load capacity of the bearing is lower

than the 70/72 series.

MONTON B719XX extremely light Series Angular Contact Ball Bearings are mainly suitable for

light-load, high-speed and high-rigidity applications. Machine tool applications such as

high-speed milling machines, machining centers and grinders have high requirements for

positioning accuracy and need to generate very little heat. The B719XX extremely light Series

Angular Contact Ball Bearings can meet the requirements of these applications and have high

rigidity at high speeds, making them a suitable solution for such applications. MONTON

B719XX extremely light Series Angular Contact Ball Bearings are loaded with the largest

number of small balls.

Smaller and lighter balls reduce the centrifugal load acting on the outer ring raceway, thereby

reducing the rolling contact surface stress. Since smaller balls require less space, the bearing

rings have a larger cross-sectional height, making them insensitive to deformation caused by

irregularities in the bearing mounting surface, bearing seat or shaft. The outer ring of the

direct-lubricated bearing has an annular groove with two lubrication holes and two annular

grooves equipped with O-rings for direct oil lubrication. In applications where high speeds are

required, bearings equipped with ceramic balls and capable of direct oil lubrication can exert

their performance.

MONTON's different bearing variant designs include:

1. Single installation U (universal) or assembled in group ad D (Double) T (Triple) Q (Quater), etc.

2. Universal bearings or universal bearing sets

3. Bearings using steel balls or hybrid ceramic ball bearings

4. Open bearings or bearings with seals on both sides

5. Bearings directly lubricated through the circumferential lubrication grooves and

radial lubrication holes on the outer ring of the bearing

6. Preload is divided into three types: light L, medium M, and heavy H

Main applications include:

1. Machining center

2. Milling machine/lathe/boring machine

3. External cylindrical and surface grinders

4. Cutting or polishing stone and glass Machine tools

5. Semiconductor industry, etc., fault detection unit on silicon wafers

6. Marine gyro stabilizers

7. Telescopes

8. Gas turbine engines

9. Racing/supercar wheels

10. Medical equipment

11. Spindle for PCB drilling

12. Woodworking machine tools

13. Turbomolecular pumps

Our company has professional sales and technical engineers who are responsible for providing

users with technical consultation, technical services and product technical training on precision

bearing information and installation and application. Perfect pre-sales, in-sales and after-sales

services constitute a guarantee system for high-quality services, providing users with reliable

quality bearing products, and creating excellent user experience and rich benefits for every user.

If you have any questions about products and services, please contact the company's service

department directly.

English

English Russian

Russian Chinese

Chinese