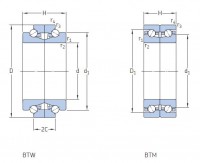

BTW BTM high-speed angular contact thrust ball bearings

|

|

MONTON double direction angular contact thrust ball bearings are designed to locate spindle shafts in both directions. These bearings combination with cylindrical roller bearings in the NN 30 K or N 10 K series in the same housing bore. This bearing combination simplify machining of the housing bore.

Double direction angular contact thrust ball bearings are manufactured with the same nominal bore size and outside diameter as corresponding cylindrical roller bearings. However, the outside diameter tolerance of the housing washers, combined with the housing bore diameter and geometric tolerances recommended for super-precision cylindrical roller bearings under light to normal load and rotating inner ring load will result in an appropriate radial clearance in the housing bore. This clearance is sufficient to prevent radial loads from acting on the thrust bearing provided that its outer ring is not axially clamped in the housing.

MONTON have two designs of double direction angular contact bearings:

BTW series and BTM series,Both designs are available either with steel balls or ceramic balls (hybrid bearings). BTM and BTW series bearings share the same bore and outside diameters.But BTM series bearings have a 25% lower bearing height , which makes them particularly suitable for compact arrangements. They do not have the same load carrying capacity and axial stiffness as bearings in the BTW series, but can operate at higher speeds.

BTW series Basic design bearings:

BTW series consist of two single row angular contact thrust ball bearings with a 60° contact angle, arranged back-to-back. This configuration, combined with the large number of balls, enables these bearings to accommodate high axial loads in both directions and provides a high degree of system rigidity. Bearings in the BTW series are separable. When the shaft washers are pressed together, preload within a predetermined range will result. BTW series can be provided with an annular groove and three lubrication holes in the housing washer.

BTM series High-speed design:

Bearings in the BTM series consist of two non-separable single row angular contact ball bearings arranged back-to-back. They are design to accommodate axial loads in both directions. When the inner rings are pressed together, preload within a predetermined range will result.

These high-speed design bearings are available with two different contact angles:

※ 30° contact angle, designation suffix A

※ 40° contact angle, designation suffix B

Bearings with 30°contact angle can accommodate higher speeds and bearings with 40° contact angle are more suitable for applications that require a higher degree of axial rigidity.

According to the ISO definition, BTM series bearings are radial bearings because they have 30° or 40°contact angle.

Hybrid bearings

Hybrid angular contact thrust ball bearings (designation suffix HC) have rings made of

bearing steel and rolling elements made of bearing grade silicon nitride ceramic. As ceramic balls are lighter and have a higher modulus of elasticity and lower coefficient of thermal expansion than steel balls, hybrid bearings can provide the following advantages:

※higher degree of rigidity

※higher speed capability

※reduced centrifugal and inertial forces within the bearing

※minimized stress at the outer ring rolling contacts at high speeds

※reduced frictional heat

※less energy consumption

※extended bearing and grease service life

※less prone to skid smearing damage and cage damage when subjected to frequent

rapid starts and stops

※less sensitive to temperature differences within the bearing

※more accurate preload control

Preload

Double direction angular contact thrust ball bearings are manufactured so that they have a suitable operating preload when mounted. Bearings in the BTM series are available with different preload:

※light preload, designation suffix DBA

※heavy preload, designation suffix DBB

The preload is obtained during manufacturing by precisely adjusting the standout of the shaft washers / inner rings relative to their housing washers / outer rings. The preload values are listed in table 5 and apply to new bearings prior to mounting. Bearing components and bearing sets must be kept together as supplied and mounted in the indicated order. For additional information, refer to Markings on bearings.

Axial stiffness

Axial stiffness depends on the elastic deformation of the bearing under load and can be expressed as a ratio of load to deflection. However, since the relationship between deflection and load is not linear, only guideline values can be provided. These values apply to mounted bearings under static conditions and subjected to moderate loads. More accurate values for axial stiffness can be calculated using advanced computer methods.

Our company has professional sales and technical engineers who are responsible for providing users with technical consultation, technical services and product technical training on precision bearing information and installation and application. Perfect pre-sales, in-sales and after-sales services constitute a guarantee system for high-quality services, providing users with reliable quality bearing products, and creating excellent user experience and rich benefits for every user.

If you have any questions about products and services, please contact the company's service department directly.

English

English Russian

Russian Chinese

Chinese