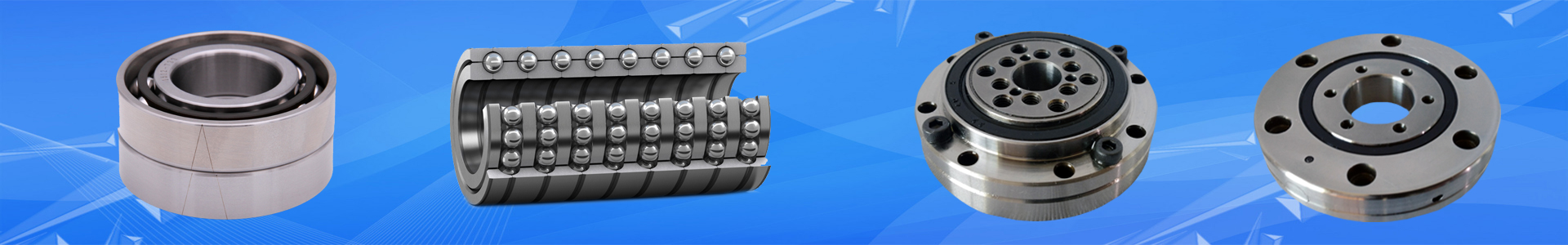

Emergency Touchdown Auxiliary Bearings

|

|

Emergency Touchdown/Auxiliary Bearings systems provide a practical method of suspending shafts (both axially and radially) in numerous applications, including turbo molecular vacuum pumps, dry pumps, compressors, blowers, air conditioning systems, gas expanders and in energy storage systems as emergency back up power.

This special application area requires bearings that can withstand the harshest conditions. To successfully control a shaft on which the magnetic bearings have failed often requires a bearing that can accelerate from zero to 2 million dN or higher virtually instantaneously.

In addition the bearing system must then control the rotor under the very high radial, axial and shock loading.MONTON has developed bearings for this application using a “full of balls” ceramic design with Special coating to give exceptional performance and corrosion resistance. MONTON is able to optimize the bearing design for the maximum number of touchdowns.

Our engineers are able to closely predict the initial shock load characteristics during the crucial first phase of operations and therefore size the touchdown bearing more appropriately. This means an emergency bearing design is not over-engineered or under-engineered for a given application. Touchdown bearings have been developed in numerous configurations, including single and double bearing arrangement.

Our Designs range from units that fit 4mm diameter shafts up to 120mm OD. For particularly harsh environments such as aggressive gases, the bearings use zirconia balls for extra corrosion resistance. MONTON’s Product Engineering Department is able to offer further advice on touchdown bearings for industrial applications by request.

Emergency Touchdown/Auxiliary Bearings Advantage:

1.High speed design ensures excellent short-term ultra high speed performance of this type of bearing;

2.The structure design of the ceramic ball deep groove ball bearing without a retaining frame and filled with ball holes enables this type of bearing to withstand greater loads;

3.The open fit and large radial clearance enable the bearing to meet high acceleration requirements;

4.High purity alloy steel and special heat treatment process greatly improve the impact resistance of bearings, which can protect magnetic levitation bearings from damage for more than 10 times;

5.Sputtering molybdenum disulfide solid lubricant on the inner ring of the bearing to prevent sintering and adhesion between the rotor shaft diameter and the inner diameter of the protective bearing under high-speed and high acceleration conditions;

6.The inner and outer rings of the bearing have undergone anti-corrosion treatment to prevent corrosion and failure caused by long-term non operation of the protected bearing; Due to the use of a fully loaded ceramic ball structure, insulation is provided between the inner and outer rings of the protective bearing, thereby avoiding the possibility of electrical corrosion in the bearing.

7. The angular contact series adopts a 25 ° contact angle design and face-to-face DF assembly method, which can provide good buffering effect when the bearing group is subjected to huge impact, thereby extending the service life of the protective bearing group;

sorry,there are no info now!

English

English Russian

Russian Chinese

Chinese